Piston and Ring Kits for Lawn Mowers

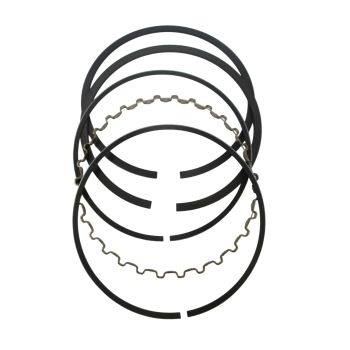

Lawn mower pistons and rings play a crucial role in maintaining efficient engine performance and smooth power delivery. They hold cylinder compression, reduce friction, and ensure smooth operation under various mowing conditions.

Proper installation and maintenance of lawn mower connecting rod and related components are equally important for smooth engine function. The connecting rod links the piston to the crankshaft, converting reciprocating motion into rotation that powers the blades. Tools like a piston ring compressor make installation easier and help prevent damage to the rings during assembly.

Over time, these parts may wear from heat, friction, and carbon buildup, causing reduced engine power or increased oil consumption. Regular inspection and timely replacement help keep your mower engine running at peak performance.

WholeToolBox supplies high-quality piston and ring kits, including lawn mower engine piston 0.50mm L, Lawn mower ring sets, and Lawn mower piston assembly 0.20", compatible with leading manufacturers such as MTD, Kawasaki, Briggs & Stratton, Ariens Company, and Honda.

FAQs

How do I replace the piston on my lawnmower?

To replace a lawn mower piston, first remove the cylinder head and old piston, then install the new piston with correct orientation using piston rings. Reassemble the cylinder, connecting rod, and head, following the manufacturer’s torque specifications.

How to tell if lawn mower piston rings are bad?

Bad piston rings often cause excessive smoke, loss of compression, and reduced engine power. Perform a compression test or inspect for scoring on the cylinder wall to confirm wear.

What are two signs of worn piston rings?

Two common signs of worn piston rings are blue or black exhaust smoke and noticeable loss of engine power or compression. These indicate the rings are failing to seal the combustion chamber properly.

What is a piston ring compressor, and how is it used?

A piston ring compressor is a tool that compresses piston rings to allow easy insertion into the cylinder bore. Place the rings over the piston, tighten the compressor, and carefully slide the piston into the cylinder.

What commonly goes wrong after piston rings?

After replacing piston rings, common issues include improper seating, causing compression loss, cylinder scoring, or oil burning. Ensuring correct installation and proper break-in procedures helps prevent these problems.

Validate your login