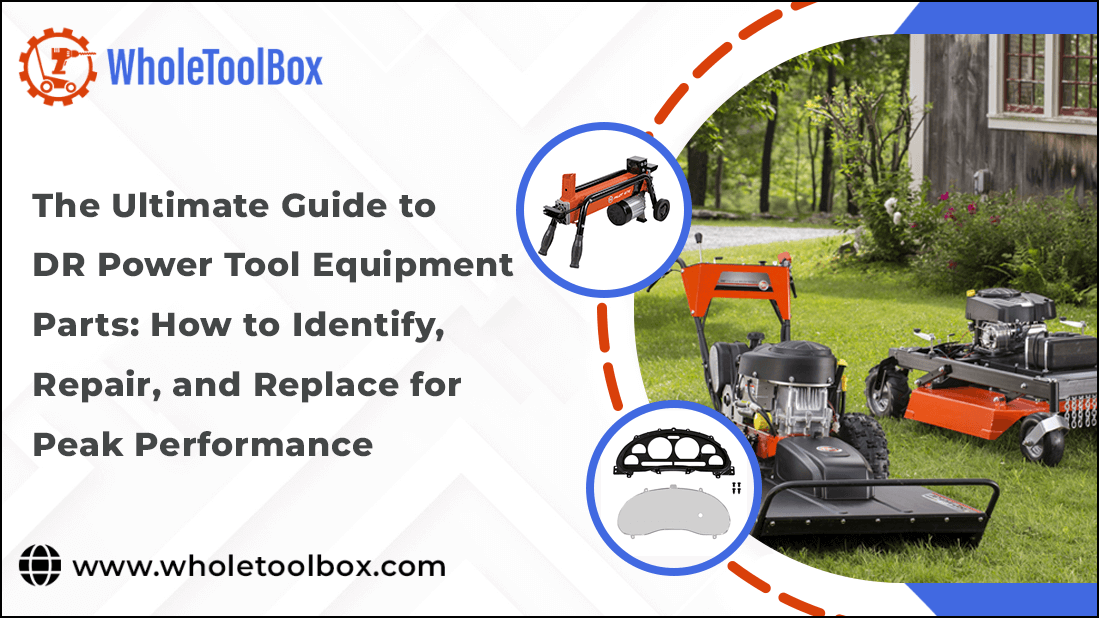

DR power tools are known for their durability and high performance, but like any equipment, they require regular maintenance to operate at their best. Knowing how to identify, repair, and replace key parts is essential for keeping your tools running smoothly. This guide covers the most important DR Power Tool components, offering practical advice on troubleshooting common issues and performing repairs. Whether you’re working with a mower, chipper, or tiller, proper care will help prevent costly repairs and extend the life of your DR parts. With clear instructions and expert tips, you’ll be well-equipped to maintain your tools and ensure they deliver reliable, long-lasting performance for every task.

Key DR Power Tool Parts Every Owner Should Know

Understanding the essential DR power tool parts is the first step in effective maintenance and repair. Here are the key components that every owner should be familiar with:

Engine: The engine powers the tool and dictates its performance, making its maintenance essential for optimal operation.

Air Filter: A blocked air filter can lower engine performance and lead to overheating, as it prevents debris from entering the engine.

Spark Plug: A worn spark plug can improperly ignite the fuel, hindering engine starting or resulting in subpar performance.

Fuel System (Carburetor/Fuel Lines): The carburetor mixes fuel and air, while fuel lines transport gas; clogs or leaks in either can lead to starting issues or reduced performance.

Blades and Cutting Mechanisms: Dull or damaged blades in tools like mowers or trimmers reduce cutting efficiency and put extra strain on the engine.

Drive Belts and Pulley System: These parts transfer power from the engine to the wheels or cutting mechanisms, and wear can lead to poor performance or failure.

Battery (for Electric Models): The battery powers electric models, and over time, it loses charge capacity, requiring eventual replacement.

Chassis and Frame: The chassis or frame holds the components together, and rust, cracks, or dents can weaken the tool’s integrity and functionality.

Understanding these parts will help you identify issues, perform routine maintenance, and replace components before they result in major damage.

Looking to keep your DR power tools in top shape? At WholeToolBox, we offer replacement parts, engines, spark plugs, and carburetors from leading brands Dr Power Equipment, Briggs & Stratton, Husqvarna, and Echo, all designed for durability and high performance.

Common Issues With DR Power Tool Parts

Understanding common issues with DR parts is crucial for effective maintenance and quick power tool repairs. Below are some typical problems associated with each major component:

Engine

Hard Starting or No Start: Difficult starting or failure to start is commonly due to stale fuel, clogged fuel filters, or worn spark plugs.

Engine Misfires or Stalls: This can occur if the carburetor is dirty or the air filter is clogged, preventing the engine from running smoothly.

Air Filter

Clogged Filter: Engine overheating or rough operation might result from airflow restriction caused by a dirty or clogged air filter.

Reduced Power: A clogged filter reduces fuel combustion efficiency, causing the engine to lose power and underperform.

Spark Plug

Starting Issues: The engine may not start due to improper ignition caused by a dirty or damaged spark plug.

Misfires: A damaged spark plug leads to irregular ignition and engine misfires, affecting performance.

Fuel System

Clogged Carburetor: Old or contaminated fuel can gum up the carburetor, hindering smooth operation.

Leaking Fuel Lines: Cracked or loose fuel lines can lead to fuel leaks, reducing efficiency and creating a safety hazard.

Blades and Cutting Mechanisms

Dull Blades: Over time, blades lose sharpness, leading to uneven cuts and added strain on the engine.

Broken Blades: Hitting rocks or debris can break or bend blades, impacting cutting performance and overall efficiency.

How to Identify When DR Power Tool Equipment Parts Need Repair or Replacement

Knowing when parts in your DR parts need repair or replacement is crucial for optimal performance. Here are the signs and how to identify them:

Loss of Power or Efficiency:

When to Repair: If performance gradually declines, cleaning or adjusting parts like air filters, spark plugs, or carburetors can restore efficiency.

When to Replace: If power loss persists after repairs, the engine or carburetor may need replacement.

Excessive Vibration or Unusual Noise:

When to Repair: Loose parts such as bolts, drive belts, or engine mounts can often be tightened or realigned.

When to Replace: Persistent vibration may require replacing worn-out parts like the engine or drive belts.

Frequent Stalling or Difficulty Starting:

When to Repair: Stalling after multiple attempts can usually be fixed by cleaning or replacing the spark plug, fuel lines, or Dr power tool carburetor.

When to Replace: If stalling continues, parts like the engine or fuel system may need replacing.

Visible Physical Damage:

When to Repair: Minor cracks or rust can be fixed with touch-ups or reinforcing the frame, or cutting the deck.

When to Replace: Severe damage to the frame or engine housing requires part replacement for safety and functionality.

Battery Performance Issues (Electric Models):

When to Repair: Dirty contacts or faulty wiring can often be cleaned or repaired.

When to Replace: If the battery no longer holds a charge or charges inefficiently, it should be replaced.

By recognizing these signs early, you can decide whether to repair smaller issues or replace worn-out components, helping to keep your DR Power Tools running at their best.

Check out this guide on spotting issues with outdoor power equipment to easily identify and address common problems, ensuring your tools stay in top condition.

Step-by-Step Repair and Replacement of DR Power Tool Parts

Repairs and replacements are manageable with the right tools and knowledge. Use this guide for common repairs and DR power tool troubleshooting.

Step 1: Diagnose the Problem

Identify Symptoms: Before you begin, carefully observe the tool for any unusual sounds, vibrations, or performance issues. Common problems include engine failure, reduced power, or difficulty starting.

Inspect for Visible Damage: Check for wear or damage on parts like belts, blades, and filters.

Consult the Manual: Refer to the DR power tool manual for troubleshooting and to understand specific part names and diagrams.

Step 2: Gather Necessary Tools and Parts

Essential Tools: Common tools needed for repairs include screwdrivers, wrenches, pliers, and socket sets.

Order Replacement Parts: Order authentic DR power tool parts after you've identified which parts are damaged. Ensure compatibility by cross-referencing the part numbers with the tool's model.

Step 3: Turn Off and Unplug the Equipment

Safety First: Before beginning any repairs, make sure the tool is unplugged from all power sources. To prevent spillage with gas-powered tools, make sure the fuel tank is empty.

Step 4: Disassemble the Tool

Remove Covers and Guards: Start by removing the tool's outer covers and safety guards, which will give you access to the internal components.

Keep Track of Fasteners: As you disassemble the tool, keep track of all screws, bolts, and fasteners, organizing them for easy reassembly.

Step 5: Remove the Faulty Part

Loosen Bolts and Fasteners: Use appropriate tools to remove the faulty part. Make a note of any special assembly instructions and the orientation.

Check for Additional Damage: While the part is removed, inspect other surrounding components for any additional wear or power tool issues.

Step 6: Install the New Part

Place the New Part: Position the new part exactly where the old one was. Make sure it is firmly attached and aligned correctly.

Tighten Fasteners: Use a wrench or screwdriver to reattach bolts and screws, but avoid over-tightening to prevent damage.

Step 7: Reassemble the Tool

Replace Safety Guards and Covers: Once the new part is installed, reassemble the tool by replacing any covers, guards, and external components.

Verify the Correct Fit: Make sure there are no loose parts and that every component fits tightly.

Step 8: Test the Tool

Perform a Test Run: Once the tool is reassembled, test it to ensure the repair was successful. Verify that everything is operating as it should and listen for odd sounds.

Monitor Performance: If the tool runs smoothly, the repair is complete. Reevaluate the repair and make sure all connections were made correctly if problems continue.

Follow these step-by-step instructions to maintain and repair your DR Power tools for optimal performance.

Maintenance Tips for Peak Performance and Longevity

To keep your DR power tools in top shape and ensure a long lifespan, regular maintenance is crucial. Here are some essential tips for peak performance:

Regular Cleaning: After every use, clean your tool to get rid of trash, leaves, and dirt. For the engine, vents, and cutting components, use compressed air or a soft brush.

Change the Oil: To ensure adequate lubrication, change the oil in gas models at least once a season or every 50 to 100 hours.

Inspect and Replace the Air Filter: Check the air filter for dirt or damage. Clean it or replace it every season for better engine performance.

Sharpen or Replace Blades: Blades should be regularly sharpened for effective cutting. Replace damaged blades to avoid engine strain.

Check the Spark Plug: Inspect for wear or carbon buildup. Clean or replace it to maintain strong engine performance.

Check Fasteners: Tighten loose bolts, screws, or nuts to prevent vibrations and performance issues.

Examine the Fuel System: Check for leaks in fuel lines and clean or replace them with a DR power tool carburetor as needed.

Lubricate Moving Parts: Apply lubrication to parts like the drive belt to prevent wear and ensure smooth operation.

By following these easy practices, you can maintain optimal performance and avoid costly power tool maintenance repairs.

Check out this guide on ultimate power tool maintenance to keep your tools in top condition and avoid costly repairs.

Conclusion

Properly maintaining, repairing, and replacing parts in your DR parts is key to maximizing performance and longevity. By identifying power tool issues like power loss, excessive vibration, or difficulty starting, you can address problems early to avoid costly repairs. Regular tasks such as replacing spark plugs, fixing fuel systems, or sharpening blades keep your tools performing at their best. Timely repairs also ensure reliability and efficiency for every task. By applying the tips and techniques in this guide, you'll be well-equipped to carry out repairs and replacements with ease, saving you both time and money. Regular maintenance will keep your equipment running smoothly and ensure it stays reliable for years to come.

FAQs

How do I know when a DR power tool part needs to be replaced instead of repaired?

If a part is severely worn, damaged beyond repair, or causing persistent issues despite maintenance, it’s time for replacement. Parts like spark plugs, air filters, and blades often need replacing after prolonged use to maintain performance.

What are the most common DR power tool parts that fail and how can I fix them?

Common parts that fail include spark plugs, air filters, and drive belts. To fix them, replace the damaged parts with OEM replacements and ensure proper installation to restore your tool’s functionality.

What are the most common DR power tool parts that need replacement?

The most common parts that need replacement include spark plugs, air filters, fuel lines, blades, and drive belts. These parts experience wear and tear over time, leading to reduced performance or malfunction.

Can I repair my DR power tool parts myself?

Yes, many DR power tool parts can be repaired or replaced with basic tools and a little know-how. For tasks like changing the spark plug or replacing the air filter, DIY is often feasible. However, for more complex issues, such as engine or carburetor repairs, professional help is recommended.

Validate your login