A lawn mower belt is a vital component responsible for delivering power from the engine to the cutting blades and drive system, directly influencing performance, safety, and reliability. This guide provides a structured overview of lawn mower belt types, the common reasons belts fail prematurely, and how belt systems transmit power across essential components. It also outlines key warning signs that indicate replacement is necessary, explains systematic troubleshooting steps, and presents practical DIY solutions for common lawn mower belt related issues. The guide concludes with guidance on performance testing and preventive practices to help ensure consistent operation and extend belt service life.

Types of Lawn Mower Belts

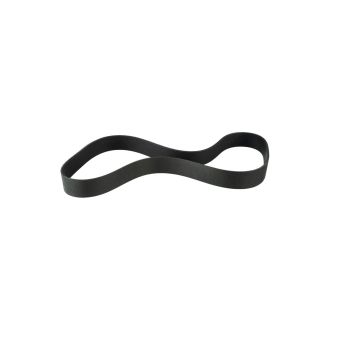

Lawn mowers use several types of belts to transfer power efficiently and ensure smooth operation. The main types include deck belts, drive belts, idler or tensioner belts, and auxiliary belts. The lawn mower belt tensioner maintains proper belt tension to prevent slippage and reduce premature wear during operation.

Why Lawn Mower Belts Fail Faster Than Expected

Lawn mower belts often fail earlier than anticipated due to a combination of mechanical, environmental, and maintenance-related factors.

Heat and Friction Buildup: Continuous operation under heavy loads generates heat. When belts slip or run under improper tension, excessive friction accelerates rubber breakdown and glazing.

Debris Accumulation: Grass clippings, dirt, and moisture trapped around pulleys increase resistance and reduce belt grip. Over time, this debris causes uneven wear and overheating.

Misalignment: Belts that are too loose slip constantly, while overtightened belts strain bearings and pulleys. Misaligned pulleys force belts to twist, leading to cracking and edge wear.

Incorrect Belt Installation: Using an incompatible belt or incorrect routing places uneven stress on the belt, shortening its lifespan significantly.

Environmental Exposure: Rubber belts naturally degrade due to UV exposure, humidity, and temperature fluctuations, even when the mower is not in frequent use.

Recognizing these contributing factors allows mower owners to address underlying causes rather than repeatedly replacing belts.

How Lawn Mower Belt Systems Transfer Power Across Components

A lawn mower belt system operates as a mechanical link between the engine and driven components. When the engine crankshaft rotates, it turns the primary drive pulley. The belt wraps around this pulley and transfers rotational energy to secondary pulleys connected to blades, wheels, or transmissions.

Pulley Interaction: Pulleys guide the belt and maintain direction while ensuring smooth power delivery. Grooved pulleys help prevent slippage, while flat pulleys assist in tension control.

Tension Mechanisms: Idler pulleys and spring-loaded arms regulate belt tension. When the operator engages the blade or drive lever, these components tighten the belt, allowing efficient power transfer.

Engagement and Disengagement: Most mowers use engagement cables or clutches to control belt contact. When disengaged, the belt relaxes, stopping blade or wheel movement without shutting off the engine.

This system depends on precise alignment and tension. Even minor deviations can reduce efficiency, increase wear, and compromise mower safety.

Common Signs Your Lawn Mower Belt Needs Replacement

A failing mower belt can affect blade performance, self-propulsion, and overall mower operation. The most common signs fall into three categories: performance-related symptoms, physical and audible indicators, and operational irregularities.

Performance-Related Symptoms

These include issues like slipping blades, loss of drive, or uneven cutting that indicate the belt is no longer transferring power effectively.

Slipping: If the mower runs normally but the blades spin slowly, or a self-propelled mower fails to move, the belt may be stretched or worn.

Uneven or Poor Cutting: A slipping deck belt can leave patches uncut or create jagged lines, reducing mowing efficiency.

Rough Operation: Excessive vibration or pulsing while mowing can indicate a misaligned or worn belt.

Physical and Audible Indicators

Visible wear or unusual noises can signal that the belt is stressed and may fail soon.

Visible Belt Damage: Cracks, fraying, missing pieces, or glazed areas indicate overheating or slippage.

Squealing or Chirping Noises: High-pitched sounds when blades or drive engage suggest belt fatigue or tension loss.

Burning Rubber Smell: Overheating belts may emit a burning odor, sometimes with blackened spots, requiring immediate replacement.

Operational Irregularities

Problems with belt tension or inconsistent engagement can disrupt mower performance and reduce cutting efficiency.

Loose or Slacked Belt: A slack belt cannot transfer power effectively to blades or drive wheels.

Blade Engagement: Temporary loss of grip can cause inconsistent movement or hesitation of the blades.

Explore lawn mower muffler repair and replacement: DIY vs. professional cost breakdown for a clear comparison of costs and benefits.

Steps to Troubleshoot Lawn Mower Belt Problems

Before replacing a mower belt, it is important to identify the root cause of the issue. Many belt problems result from misalignment, debris buildup, or pulley damage rather than belt wear alone. Follow these steps to troubleshoot effectively:

Step 1: Perform a Safety Check

Turn off the mower and disconnect the spark plug wire.

Allow the engine and mower deck to cool completely.

Engage the parking brake or block the wheels to prevent accidental movement.

Step 2: Inspect the Belt Condition

Look for cracks, splits, fraying, or missing chunks.

Check for stretching, looseness, or improper tension.

Inspect for oil, grease, or debris contamination that could reduce grip.

Step 3: Examine Pulleys and Idlers

Ensure pulleys spin freely without wobbling or unusual noise.

Check for bent or damaged pulley edges.

Confirm idler arms move smoothly and maintain proper tension.

Step 4: Verify Belt Routing

Compare the belt path to the manufacturer’s diagram.

Look for twists, misalignment, or incorrect positioning.

Ensure the belt sits fully inside the pulley grooves.

Proper troubleshooting helps identify whether a belt truly needs replacement or if another component is causing the issue. Addressing these problems early ensures safe & efficient mower operation.

DIY Lawn Mower Belt Replacement Solutions for Common Issues

Understanding how to replace a belt on a riding lawn mower starts with following the correct routing, tensioning, and safety procedures. Below are the most common belt-related issues and effective DIY solutions.

#1 Issue: Belt slipping during operation

Solution: Inspect the belt for glazing or stretching and replace it if wear is visible. Confirm the belt follows the manufacturer-specified routing to ensure proper pulley contact. Clean all pulleys to remove grass, oil, or debris that may reduce grip. Adjust the belt tension to factory specifications to restore efficient power transfer.

#2 Issue: Belt coming off the pulleys

Solution: Check all pulleys for misalignment, wobble, or looseness and secure or replace damaged components. Inspect belt guides and guards to ensure they are intact and correctly positioned. Verify that the belt size matches the mower model requirements to prevent derailment during operation.

#3 Issue: Excessive belt wear or cracking

Solution: Remove accumulated grass and debris from the mower deck to reduce heat buildup. Ensure the belt is routed correctly and does not rub against metal edges. Inspect pulleys and idlers for smooth rotation and replace any components that bind or resist movement to minimize premature wear.

#4 Issue: Blade not engaging after belt replacement

Solution: Confirm the belt is fully seated in all pulley grooves and free from twists. Inspect the blade engagement cable, clutch, and tension spring for wear or incorrect adjustment. Adjust cable tension as needed to ensure proper blade engagement when activated.

#5 Issue: Squealing noise or burning smell from the belt

Solution: Stop the mower immediately and inspect the belt for signs of overheating or glazing. Check pulley alignment and verify that all rotating components spin freely. Adjust the belt tension according to the manufacturer's guidelines and replace any damaged belts to prevent further mechanical issues.

For homeowners learning how to change the belt on riding lawn mower models, following these corrective steps helps ensure reliable engagement and smooth operation after replacement.

Read on & find out How to Replace Lawn Mower Belts: A Step-by-Step Guide

Testing Performance and Preventing Future Lawn Mower Belt Failures

After replacing or adjusting a mower belt, it’s important to test performance and implement practices that prevent premature failures:

Post-Repair Test Run: Start the mower and engage the blades or drive system. Check for smooth belt movement, consistent blade speed, and even cutting results. Any squealing, vibration, or slipping indicates a need for further adjustment.

Verify Belt Tension: Press on the longest straight section of the belt to confirm proper tension. The belt should have slight movement without excessive slack. Adjust tension according to manufacturer guidelines to avoid slippage or component strain.

Inspect Pulleys and Alignment: Ensure all pulleys are clean, aligned, and rotate freely. Worn or misaligned pulleys place added stress on the belt and can lead to early failure.

Maintain Cleanliness: Remove grass clippings and debris from the belt area after each use to reduce friction and heat buildup.

Routine Checks and Storage: Inspect belts regularly for wear and store the mower in a dry, shaded area to protect the belt from environmental damage.

These practices not only verify that your mower operates efficiently after a repair but also help minimize the risk of belt issues recurring, keeping your equipment dependable over time.

Conclusion: Ensure Reliable Belt Performance for Smooth Operation

A well-maintained lawn mower belt is essential for safe operation, consistent cutting performance, and overall mower reliability. By recognizing early signs of wear such as slipping, cracking, or unusual noises and applying proper DIY replacement techniques, you can prevent unexpected breakdowns, reduce maintenance costs, and extend the belt’s service life. Regular inspections, correct tension adjustments, clean pulleys, and adherence to manufacturer guidelines ensure smooth power transfer and long-term equipment efficiency.

Key Takeaways

The belt transfers engine power to the blades and drive system for efficient operation

Early warning signs include slipping, uneven cutting, squealing noises, and visible wear or cracks

Proper tools, correct belt routing, and safety precautions are crucial during replacement

Minor damage can often be repaired; severely worn or damaged belts require replacement

Regular inspection, cleaning, and proper tension prevent premature failures and maintain smooth operation

Preventive care not only protects the mower but also enhances safety and performance during every mowing session. Maintaining your mower belt proactively ensures reliable performance and allows you to enjoy a safe, efficient, and long-lasting mowing experience.

FAQs

How do I adjust the tension on my lawnmower belt?

Turn off the mower and disconnect the spark plug. Adjust the tensioner or idler pulley so the belt is snug but not too tight. Follow manufacturer specifications.

Why is my lawn mower belt not engaging?

Check for a misaligned or worn belt, loose engagement cable, or faulty clutch. Adjust the cable and ensure the belt is properly seated.

Why does my mower keep chewing up belts?

Common causes are misaligned pulleys, debris, over-tightened belts, or using the wrong belt size. Inspect pulleys, clean debris, and use the correct belt.

Why does my lawnmower leave a strip of grass in the middle?

A slipping or worn deck belt or dull blade can cause this. Check belt tension, blade condition, and pulley alignment. Replace or sharpen as needed.

Validate your login