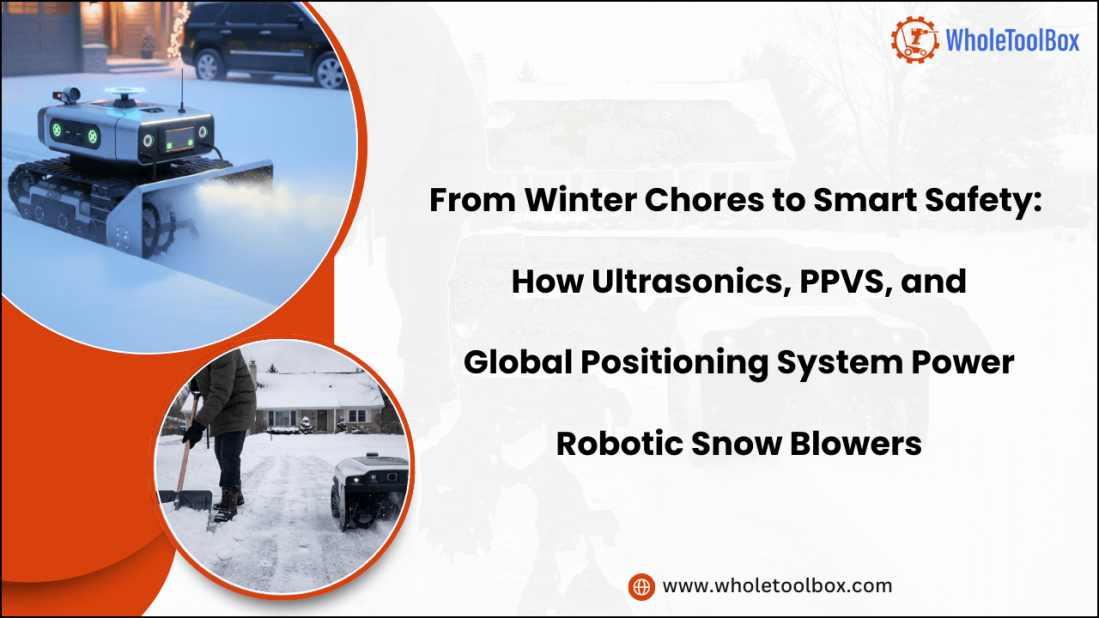

Winter snow removal is often tedious, time-consuming, and can pose serious safety risks. Robotic snow blowers are transforming this chore by operating quietly and efficiently while protecting people and property. Leveraging advanced technologies such as ultrasonic sensors, PPVS (Precision Path and Vision Systems), and GPS, these machines navigate snowy landscapes with precision, detect hidden obstacles, map paths intelligently, and maintain accurate positioning. In this article, we explore the evolution of snow removal, the innovative technologies powering robotic snow blowers, their real-world impact in residential and commercial settings, and the challenges and future innovations in robotic snow blower safety.

The Evolution of Snow Removal: From Manual to Autonomous

Snow removal has evolved from basic manual labor to advanced autonomous systems. Early methods relied on shovels, snow rollers, and horse-drawn plows that flattened or pushed snow aside. As cities grew, motorized plows, snow blowers, and salt spreaders emerged to keep roads safe and functional. Today, robotic snow blowers represent the next stage of this evolution, using sensors, GPS, and intelligent software to clear snow automatically. This shift reduces physical effort, improves safety, and delivers more efficient and reliable winter maintenance.

What Are Robotic Snow Blowers and How Do They Work?

Robotic snow blowers are fully autonomous machines designed to clear snow without manual operation. Unlike traditional snow blowers, they function as self-managing systems that combine mechanical snow removal with automated control logic to maintain clear surfaces consistently and safely.

Robotic snow blowers work fully autonomously, handling snow removal with minimal human input. They follow predefined areas and schedules while managing their own operation and power.

Users define clearing zones, boundaries, and restricted areas during setup.

The robot starts automatically based on schedules or snowfall detection.

Snow is cleared in slow, precise passes for even coverage and surface safety.

After finishing or when the battery is low, the robot returns to its charging station automatically.

Explore high-tech snow blowers: from single-stage to three-stage systems for efficient winter cleanup and boost performance and safety.

Smart Sensing and Navigation Technologies Behind Robotic Snow Blowers

Smart sensing and navigation technologies allow robotic snow blowers to detect obstacles, maintain precise positioning, and autonomously clear snow in low-visibility and extreme winter conditions. These systems combine ultrasonic sensors, vision-based navigation, and high-precision GPS to deliver safe, efficient, and reliable snow removal without human intervention.

Ultrasonic Sensors for Obstacle Detection: Ultrasonic sensors enable robotic snow blowers to detect nearby obstacles by emitting high-frequency sound waves and measuring the reflected echo to calculate distance. They work reliably in snowy, dark, or foggy conditions where cameras may fail. Mounted on the front and sides, these sensors provide continuous short-range monitoring. When an obstacle enters a safety zone, the robot automatically slows down, stops, or changes direction.

Key Technical Specifications | Advantages |

|

|

Precision Path Vision Systems (PPVS) for Intelligent Navigation: Precision Path Vision Systems (PPVS) enable robotic snow blowers to navigate with human-like accuracy by combining vision, positioning, and motion data. Unlike basic GPS navigation, PPVS continuously adapts to real-world conditions.

Key Components of PPVS

PPVS relies on multi-sensor fusion, including:

Stereo Cameras: Capture real-time images of terrain and obstacles

AI Vision Algorithms: Identify boundaries, snowbanks, curbs, and debris

Inertial Measurement Unit (IMU): Tracks motion, tilt, and slippage

Odometry Sensors: Estimates total distance traveled

Path-Planning Software: Generates and updates efficient snow-clearing routes

Together, these components allow the robot to maintain accurate positioning even when environmental conditions change.

Why PPVS Matters

PPVS is essential for autonomous snow removal because it:

Ensures complete area coverage with minimal overlap

Improves collision avoidance beyond GPS limitations

Maintains navigation accuracy when GPS signals degrade

Reduces battery consumption through optimized routing

GPS Integration for Accurate Mapping and Connectivity: GPS provides the foundational positioning system that allows robotic snow blowers to map, navigate, and stay within defined boundaries. Advanced models enhance GPS with correction data and smart connectivity features.

How GPS Works in Robotic Snow Blowers

Robotic snow blowers use Global Navigation Satellite Systems (GNSS) to determine their real-time location by receiving signals from multiple satellites. This positioning data enables autonomous navigation and precise area management. During the initial setup process, GPS allows the robotic snow blower to,

Map operational boundaries, such as driveways, sidewalks, and paths

Store virtual no-go zones to avoid obstacles, property edges, or restricted areas

Create and save digital maps for consistent, repeatable snow-clearing routes

While operating, the robot continuously compares its live GPS position with the stored map. This ensures it stays within defined boundaries, follows planned paths, and avoids restricted zones without requiring physical markers.

Real-World Applications and Use Cases in Residential and Commercial Settings

Robotic snow blowers are transforming snow removal for homes and businesses, offering safer, automated, and efficient clearing solutions.

Residential Applications and Use Cases

This table highlights the ways robotic snow blowers help homeowners clear snow effortlessly.

Application | Use Case | User Benefits |

Home Driveways | Keeps private vehicle entry points free of snow throughout winter | Eliminates physical effort, lowers injury risk, and ensures daily mobility |

Sidewalks & Entry Paths | Maintains safe walking routes to doors, garages, and entrances | Reduces slips and falls, improves household safety |

Shared Driveways & Private Lanes | Manages snow removal in multi-home or shared-access areas | Avoids coordination issues, ensures consistent access for all residents |

Preventive Snow Management | Removes snow early before it compacts or freezes | Minimizes ice buildup, improves long-term surface safety |

Commercial Applications and Use Cases

The table highlights how robotic snow blowers make commercial snow removal easier, safer, and less labor-intensive.

Application | Use Case | Business Benefits |

Parking Lots & Vehicle Zones | Keeps large parking areas usable during snowfall | Cuts manual labor costs, prevents vehicle obstruction |

Corporate & Office Campuses | Ensures clear movement paths for employees and visitors | Improves workplace safety and operational continuity |

Retail & Shopping Complexes | Maintains access to storefronts during business hours | Enhances customer experience, reduces liability risks |

Public Sidewalks & Pedestrian Areas | Keeps high-footfall zones safe in winter conditions | Lowers accident claims, supports regulatory compliance |

Challenges and Future Innovations in Robotic Snow Blower Safety

Below, we explore the main challenges robotic snow blowers face and the innovative technologies designed to make them safer and more efficient.

Key Safety Challenges

Robotic snow blowers face risks from harsh weather, hidden obstacles, debris, and software or connectivity issues.

Harsh Winter Conditions: Snow, ice, and freezing temperatures can block cameras and sensors, while cold weather reduces battery performance. In heavy storms, reduced visibility can cause robots to pause or lose accuracy.

Flying Debris Risks: Even with protective covers, snow blowers can throw hidden objects like rocks or ice at high speed. This remains one of the most serious physical dangers, especially near homes.

Detecting People and Pets: Snow can hide small or low objects. Children, pets, or dark objects on white snow may be hard for cameras and AI to recognize, increasing the risk of missed hazards.

Software and Navigation Errors: Robots rely on maps, GPS, and software logic. Signal loss, bugs, or corrupted maps can cause the machine to stop, wander, or behave unpredictably.

Connectivity and Security: Because robotic snow blowers connect to apps and networks, weak cybersecurity could allow unauthorized access or unsafe remote control if not properly protected.

Future Innovations Improving Safety

Advanced sensors, intelligent AI, and weather-aware systems are enhancing the safety of robotic snow blowers.

Smarter Sensors: Future models will combine cameras, LiDAR, radar, and thermal sensors so the robot can “see” reliably even in darkness or heavy snowfall.

Better AI Hazard Recognition: Improved AI will more accurately recognize people, pets, and common objects by analyzing shape, movement, and heat, reducing dangerous blind spots.

Built-In Health Monitoring: Robots will continuously check their own sensors, batteries, and motors, stopping or alerting users before problems become unsafe.

Weather-Aware Operation: By using real-time weather data, robots will choose safer times to operate and pause during severe conditions like whiteouts.

Human Control Options: Live video, remote steering, and instant emergency stop features ensure owners can step in whenever the robot faces a risky situation.

Improved Batteries and Materials: New cold-resistant batteries and lighter, impact-absorbing materials will make robots safer and more reliable in winter conditions.

Check out how to repair and replace snow blower air cleaner housing quickly: a step-by-step guide to keep your machine running smoothly and maintain optimal engine performance.

Final Thoughts: Smarter, Safer, and More Efficient Snow Management

Robotic snow blowers are transforming winter maintenance by turning a traditionally labor-intensive and hazardous task into a safe, efficient, and largely hands-free process. By combining ultrasonic sensors, Precision Path Vision Systems (PPVS), and GPS-based navigation, these machines detect obstacles, maintain precise positioning, and autonomously clear snow in residential and commercial environments.

Key Takeaways

Ultrasonic sensors enable reliable obstacle detection even in low visibility and extreme winter conditions.

PPVS allows precise navigation and optimal path planning for complete area coverage.

GPS integration ensures accurate mapping, boundary adherence, and repeatable snow-clearing routes.

Advanced AI and sensor fusion improve collision avoidance and autonomous decision-making.

Future innovations like weather-aware operation, improved batteries, and enhanced AI hazard recognition will further boost safety and efficiency.

While challenges such as harsh weather, flying debris, and connectivity issues remain, ongoing innovations in AI, advanced sensing, and weather-aware operation continue to enhance safety, reliability, and performance. These technologies are setting a new benchmark for smarter, safer, and more efficient snow management.

Upgrade your snowblower with premium parts from WholeToolBox, featuring durable snow cab kits, precision-fit skid shoes, and high-grip snow chains, compatible with CRAFTSMAN, Cub Cadet, MTD, and other trusted snowblower brands.

References:

https://www.rossandcromartyheritage.org/home/pan-ross/pan-ross-work/snow-blowers/

https://www.cumberland.gov.uk/parking-roads-and-transport/streets-roads-and-pavements/road-maintenance-closures-and-improvements/winter-road-maintenance-and-gritting/clearing-snow

FAQs

How long does a robotic snow blower last?

A robotic snow blower typically lasts 5 to 10 years with proper maintenance, including battery care, cleaning, and timely replacement of wear parts like augers or belts.

What size driveway can a robot snow blower handle?

Most robotic snow blowers are designed for standard residential driveways up to 50 to 100 feet long and about 10 to 12 feet wide. Larger driveways may require multiple passes or a higher-capacity model for efficient snow clearing.

Can a robotic snow blower handle ice?

Robotic snow blowers can manage light or moderately packed ice, but thick or hard ice may require manual tools or de-icing solutions to avoid damage and ensure effective clearing.

Validate your login