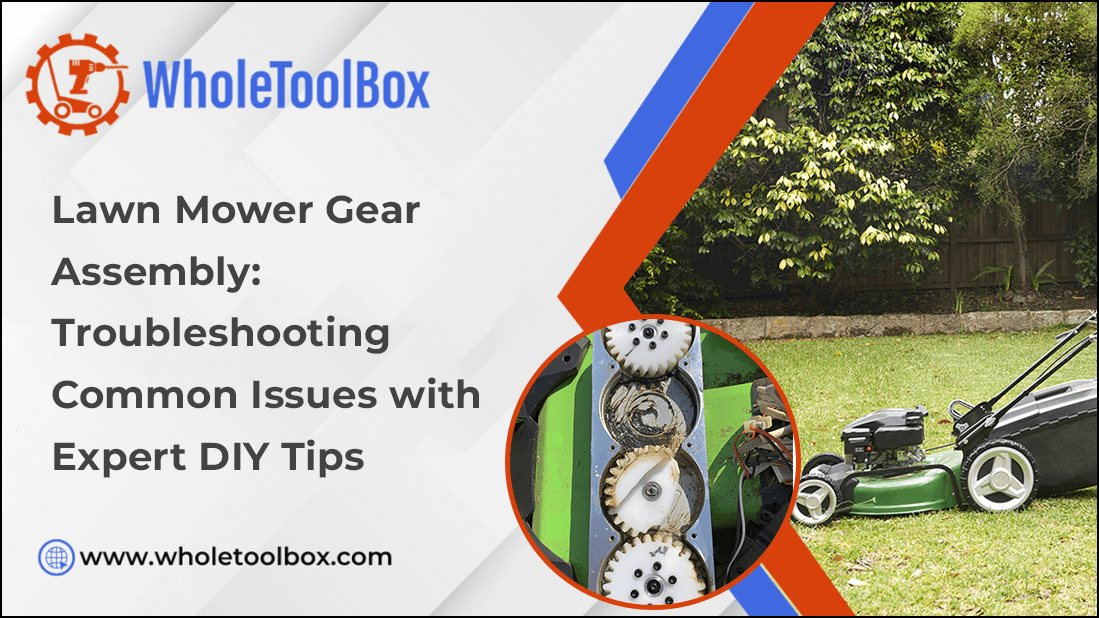

Lawn mower gear assembly is a crucial part of your mower’s drivetrain that transfers power from the engine to the wheels, allowing smooth movement and control. Over time, gears can wear out, become misaligned, or suffer from poor lubrication, causing issues like grinding noises, loss of drive, or jerky operation. Recognizing these problems early helps avoid costly repairs and mower downtime.

In this guide, you'll discover how to diagnose and fix common lawn mower gear assembly issues using expert DIY techniques. We’ll cover how to identify warning signs, perform inspections, and carry out simple repairs to keep your mower running efficiently. These practical steps help you confidently maintain and fix your gear assembly, saving time and money.

What Is a Lawn Mower Gear Assembly and Why It Matters

The lawn mower gear assembly is a vital part of the gear-driven lawn mower transmission system, transferring power from the engine to the wheels or blades. This enables smooth movement and efficient operation, especially in self-propelled and riding mowers.

Key Functions of the Lawn Mower Gear Assembly:

Power Transmission: Transfers engine power through the lawn mowing gear to the wheels or blades, enabling movement and cutting.

Speed Regulation: Helps control the mower’s speed by engaging different gear ratios.

Torque Management: Provides the necessary torque for navigating different terrains and grass densities.

Smooth Operation: Ensures consistent and smooth mower movement, reducing strain on the engine.

Why It Matters:

Efficiency: A well-maintained gear assembly improves fuel efficiency and mowing performance.

Longevity: Proper functioning extends the lifespan of your lawn mower by preventing excessive wear.

Cost Savings: Early detection and repair of gear issues help avoid expensive replacements.

User safety: Avoids sudden jerks or stops that could result in mishaps when cutting the lawn.

Understanding your lawn mower gear assembly’s role within the lawn mower transmission system is the first step toward keeping your mower and other lawn care tools in peak condition.

Looking for high-performance parts to fix your lawn mower gear assembly? WholeToolBox offers top-quality transmission assemblies, drive belts, and bearings from leading brands like Briggs & Stratton, Toro, and Husqvarna. Find all your lawn mower parts online for expert DIY repairs all in one place!

Warning Signs of Lawn Mower Gear Assembly Trouble You Shouldn’t Ignore

Recognizing early warning signs of gear assembly lawn mower problems can help you avoid costly repairs and mower downtime. Watch for these common symptoms:

Grinding or Clicking Noises: Unusual sounds during mowing often mean gears are worn, chipped, or misaligned.

Loss of Drive or Propulsion: If your self-propelled mower stops moving forward despite the engine running, the gear assembly might be slipping or broken.

Jerky or Uneven Movement: Difficulty maintaining smooth motion can signal damaged or misaligned gears.

Visible Gear Damage or Wear: Inspect for cracked, stripped, or excessively worn gear teeth.

Oil or Grease Leaks Near Gear Housing: Leaking lubricant can cause gear failure due to insufficient lubrication.

Excessive Heat or Burning: Overheated gears may emit a burning odor, indicating friction and possible damage.

Most Common Lawn Mower Gear Assembly Issues and What Causes Them

Lawn mower gear assemblies are prone to a handful of common issues that can affect your mower’s performance. Before they require expensive repairs, you may diagnose and successfully treat these issues by being aware of their causes.

Common Issues:

Worn or Stripped Gears: Over time, gear teeth can wear down or strip completely due to constant friction, poor lubrication, or debris getting trapped inside. This causes slipping and loss of drive.

Gear Misalignment: Improper installation, impacts, or worn bearings can cause gears to misalign, leading to grinding noises and uneven movement.

Lubrication Failure: Lack of proper grease or oil causes increased friction and heat, accelerating wear and potential gear seizure.

Damaged Gear Housing: Cracks or damage to the gear housing can lead to dirt and moisture entering, which causes corrosion and premature gear failure.

Broken or Worn Bearings: Bearings support the gears’ rotation; when they fail, gears don’t mesh properly, resulting in noise and inefficient operation.

Gear Slippage: Loose or damaged gear connections can cause slippage, meaning the mower won’t move as expected even when the engine runs smoothly.

By identifying these issues early, you can apply the right fixes and keep your mower operating smoothly for longer.

Must-Have Tools for DIY Lawn Mower Gear Assembly Troubleshooting

Having the right tools is essential for effective troubleshooting and repairs. Here are the key tools you’ll need:

Socket and Wrench Set

Screwdrivers (Flathead and Phillips)

Pliers

Bearing Puller

Grease Gun or Applicator

Torque Wrench

Cleaning Brushes and Rags

Safety Gear (Gloves and Safety Glasses)

DIY Troubleshooting Process: How to Identify Lawn Mower Gear Assembly Problems

When it comes to lawn mower troubleshooting, identifying gear assembly problems early is crucial. A careful inspection of the gear assembly helps pinpoint issues before they lead to bigger repairs.

Visual Inspection

For safety, turn off the mower and unplug the spark plug.

Using the proper instruments, remove the gear housing cover.

Inspect gears closely for cracks, chips, or worn teeth.

Check for dirt, debris, rust, or signs of corrosion inside the housing.

Take note of any odd wear trends or broken parts.

Listen for Unusual Noises

Start the mower in a safe, open area.

Engage the self-propel or drive system slowly.

Listen carefully for grinding, clicking, or clunking sounds.

Repeat at different speeds to identify when noises occur.

Record or note the noise type and timing for reference.

Test Gear Engagement

With the mower off, try to manually rotate the wheels.

Observe if wheels turn smoothly or feel stuck/resistant.

Check if the wheels slip or don’t engage properly when pushed.

Listen for any unusual grinding during manual rotation.

Check for Leakage

Inspect around the gear housing for any oil or grease leaks.

Look for wet spots, drips, or build-up of lubricant outside the housing.

Examine the gaskets and seals for any damage.

Note if lubrication appears dirty or contaminated.

Observe Movement

Engage the mower’s self-propel system on a flat surface.

Watch for jerky, uneven, or inconsistent wheel movement.

Note any hesitation or slipping during acceleration.

Test both forward and reverse motion if applicable.

Check out this guide on lawn mower clutch replacement: diy vs. professional cost breakdown to decide the best option for your budget and skills.

Expert DIY Fixes for Common Lawn Mower Gear Assembly Problems

Fixing your gear assembly yourself can save time and money when done carefully. Using the proper tools and methods, many common lawn mower issues can be easily fixed at home.

Gear Teeth Stripping

The teeth on the gears wear down or break, causing slippage and loss of drive.

Symptoms:

Mower wheels spin but don’t move forward

Grinding noises when engaging the drive

Jerky or uneven mower movement

Possible Causes:

Lack of lubrication

Debris or dirt caught in the gears

Overloading the mower on thick grass or slopes

DIY Fixes:

Replace Worn Gears: Remove damaged gears and install compatible new ones.

Clean Gear Assembly: Thoroughly clean housing to remove debris.

Proper Lubrication: Apply high-quality grease to reduce wear.

Check Mower Usage: Avoid overloading the mower or using it on unsuitable terrain.

Inspect Drive Belt: Ensure belt tension is correct to prevent excessive gear strain.

Gear Misalignment

Gears are not properly aligned, causing inefficient power transfer and noise.

Symptoms:

Grinding or clicking sounds during operation

Uneven or jerky wheel movement

Excessive vibration felt during use

Possible Causes:

Improper installation after maintenance

Impact or rough handling of the mower

Worn or loose mounting bolts

DIY Fixes:

Adjust Gear Position: Loosen housing, realign gears so teeth mesh properly, then retighten bolts.

Tighten Mounting Bolts: Ensure all screws and bolts are secure.

Inspect for Damage: Replace any warped or bent gears causing misalignment.

Use a Torque Wrench: Avoid overtightening or undertightening bolts by following the manufacturer's instructions.

Check Gear Shaft Bearings: Replace if worn, as loose bearings can cause misalignment.

Lubrication Failure

Gears dry out, increasing friction and accelerating wear or seizure.

Symptoms:

Loud grinding or squealing noises

Overheating gear housing

Sudden loss of mower drive

Possible Causes:

Old or contaminated grease

Leaking seals or gaskets

Lack of routine maintenance

DIY Fixes:

Clean Old Grease: Remove all old lubricant with a degreaser.

Apply Fresh Grease: Use manufacturer-recommended lubricant.

Replace Seals: Install new gaskets or seals to prevent leaks.

Regular Maintenance Schedule: Check and lubricate gears periodically.

Inspect for Contaminants: Keep gear housing clean from dirt and water that degrade lubricant.

Bearing Failure

Bearings supporting gear shafts wear out or seize, causing poor gear movement.

Symptoms:

Loud squeaking or grinding noises

Vibration or wobbling during use

Difficulty turning wheels manually

Possible Causes:

Lack of lubrication

Dirt or debris infiltration

Age and wear

DIY Fixes:

Remove and Replace Bearings: Use a bearing puller tool for safe removal.

Lubricate Bearings: Apply appropriate grease before reinstalling.

Keep Housing Clean: Prevent dirt buildup that damages bearings.

Check Bearing Fit: Ensure bearings fit snugly to avoid wobble.

Inspect Seals Around Bearings: Replace if damaged to prevent debris entry.

Gear Housing Cracks

Cracks in the housing allow dirt and moisture in, damaging gears.

Symptoms:

Visible cracks or damage on the housing

Gear noise increases over time

Premature gear wear or failure

Possible Causes:

Impact damage from hitting obstacles

Material fatigue or manufacturing defects

Corrosion from moisture exposure

DIY Fixes:

Inspect and Clean Housing: Remove dirt and moisture immediately.

Apply Epoxy Repair: Seal small cracks with strong epoxy or plastic weld.

Replace Housing: For severe damage, install a new housing unit.

Use Protective Covers: Add guards or shields to prevent impact damage.

Store Mower Properly: To prevent corrosion, keep the mower in a dry location.

Check out this guide on how to diagnose mower muffler problems: expert troubleshooting tips to quickly identify issues and keep your mower running smoothly.

Pro Maintenance Tips to Avoid Lawn Mower Gear Assembly Failures

Proper maintenance is key to preventing gear assembly failures and extending your mower’s life. These expert tips will help keep your mower running smoothly and efficiently.

Inspect and Lubricate Regularly: Check the gear assembly frequently for wear or dirt. Use premium oil to cut down on friction and shield surfaces from harm.

Keep the Gear Housing Clean: Remove debris and grass clippings from the housing during maintenance. To keep impurities out, make sure gaskets and seals are in place.

Monitor for Unusual Noises: Listen for grinding or clicking sounds during operation. To prevent expensive lawn mower gearbox repairs, look into any noises as soon as possible.

Use Correct Parts and Follow Guidelines: Replace worn parts with manufacturer-approved components. Follow torque specs and assembly instructions carefully.

Check Drive Belt Condition: Inspect belts regularly for cracks or wear. Replace damaged belts promptly to avoid stress on gears.

Perform Seasonal Gear Inspection: Before and after mowing season, thoroughly inspect the gear assembly. Address any issues early to prevent long-term damage.

Following these simple maintenance steps will help you avoid costly gear issues and ensure your mower performs at its best year-round.

Conclusion

Keeping your lawn mower gear assembly in good shape is essential for smooth and efficient mowing. By identifying common problems early and applying expert DIY fixes, you can save both time and money. Understanding how the gear assembly works and what causes typical issues empowers you to take control of your mower’s maintenance.

The keys to avoiding expensive failures include quick lawn mower gearbox repairs, appropriate lubrication, and routine inspection. With the right care, your lawn mower will perform reliably year after year. Remember, a well-maintained gear assembly means less downtime and a healthier lawn.

FAQs

Why is my lawn mower gear assembly not working?

It could be due to a worn-out gear, a jammed mechanism, or insufficient lubrication. Start by checking the gear teeth for damage and cleaning any debris that might be blocking movement.

How do I adjust the lawn mower’s gear assembly?

Adjusting the gear assembly typically involves checking the tension of the drive belt and ensuring that the gears are properly aligned. Follow your mower's manual for specific instructions.

How do I lubricate my lawn mower gear assembly?

Use a high-quality grease or oil to lubricate the gears. Apply a thin layer on the moving parts, ensuring you don’t over-lubricate, which could attract dirt and debris.

How much does a lawn mower gear assembly typically cost?

A: The cost of a lawn mower gear assembly usually ranges from $50 to $150, depending on the mower model and brand.

Validate your login