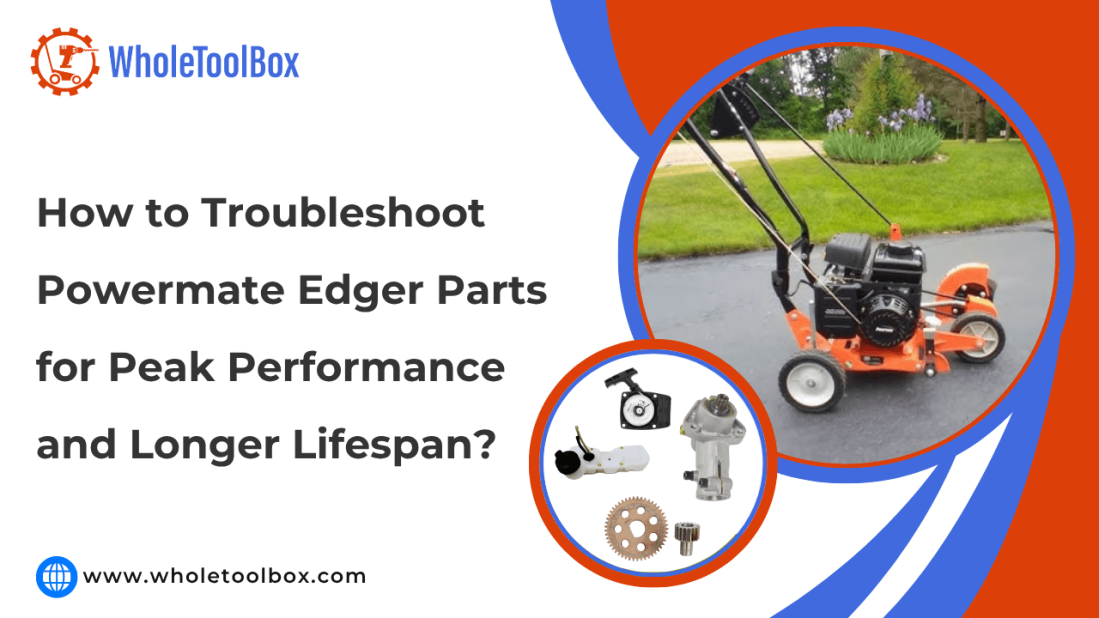

A well-maintained Powermate edger can dramatically enhance the look of your lawn, giving it those sharp, professional lines that boost curb appeal. But like any piece of outdoor power equipment, it requires regular care and attention. When your Powermate edger starts to underperform, stall, or refuse to start altogether, timely troubleshooting can make the difference between a quick fix and an expensive repair or worse, replacement.

Troubleshooting Powermate edger parts ensures your machine operates at peak efficiency, extends its service life, and saves you money in the long run. Whether you're dealing with engine issues, power loss, or blade malfunctions, knowing how to properly inspect and resolve these problems is essential. Let’s dive deep into identifying and fixing common Powermate edger issues.

Why Proper Troubleshooting Matters for Your Powermate Edger

Proper Powermate edger troubleshooting is essential for maintaining peak performance. Identifying and resolving issues early not only saves money but also reduces downtime and extends the lifespan of your equipment.

Here’s why effective troubleshooting should never be overlooked:

Prevents Minor Issues from Escalating: Detecting small problems like a loose belt or dirty air filter can prevent bigger, costlier damage down the line.

Improves Engine Performance: Addressing engine hiccups, misfires, or fuel issues ensures your edger runs smoothly, starts reliably, and delivers consistent power.

Enhances Safety During Operation: Faulty parts like worn blades, loose guards, or unstable wheels pose safety risks. Troubleshooting keeps the machine operating safely.

Increases Equipment Lifespan: Routine inspections and early repairs help reduce wear on core components, extending the overall service life of your edger.

Reduces Unexpected Downtime: Regular checks and fixes reduce the chances of sudden breakdowns, so your landscaping jobs aren’t interrupted.

Saves on Repair Costs: Early fixes often cost far less than major overhauls or complete part replacements.

Optimizes Fuel Efficiency: A well-maintained engine burns fuel more cleanly and efficiently, saving money over time.

Looking to keep your Powermate edger in top shape? WholeToolBox offers everything you need, from high-quality replacement blades, durable drive belts, to reliable spark plugs to ensure peak performance and longer lifespan. Plus,

Understanding Key Powermate Edger Components

To troubleshoot your Powermate edger effectively, you need to understand its main parts and how they work together. This knowledge helps you quickly identify the source of any problem.

Engine / Power Source: Most Powermate edgers use a 4-stroke gasoline engine that powers the entire machine.

Fuel System: Includes the fuel tank, fuel line, carburetor, primer bulb, and fuel filter, all responsible for delivering clean fuel to the engine.

Ignition System: Comprises the spark plug, ignition wire, and kill switch, which ignite the fuel-air mixture to start and run the engine.

Air Intake & Filtration: The air filter traps dust and debris, while the intake manifold and throttle linkage regulate airflow and engine speed.

Throttle & Governor Linkage: Controls engine speed under different loads and may need adjustment over time due to wear.

Drive System / Transmission: Consists of the belt and pulley assembly, shims, idler pulleys, and the clutch or engagement mechanism that powers the blade.

Blade Assembly: Includes the cutter blade, spindle, shaft, blade guard, mounting bolts, and depth control wheels to adjust cutting depth.

Frame & Safety Components: The chassis supports all parts; guard screens and vibration dampeners protect the operator and improve comfort.

Lubrication, Seals & Bearings: Bearings enable smooth rotation, while seals and lubrication protect moving parts from wear and dirt.

Understanding these components and their interactions is key to effective troubleshooting and maintenance.

Diagnosing Engine Start‑Up Problems in Powermate Edgers

When your Powermate edger won’t start, edge parts troubleshooting usually focuses on the fuel, ignition, or air systems.

Check Basic Preconditions

Fuel Supply: Ensure there’s fresh gasoline, filled properly. Gas older than about 30 days can degrade, form varnish, and clog jets.

Oil Level / Low Oil Shutoff: Many engines shut down if oil is too low. Check the oil level and top up as needed.

Kill Switch / Safety Interlock: Make sure the kill/ignition switch is set to “ON” and any safety wires are connected properly.

Choke / Primer: Use the primer and choke as directed. If the engine is cold, you may need to apply full choke initially.

Inspect Spark Plug & Ignition

Spark Plug Condition: Remove the spark plug for edger and examine it for soot, oil fouling, or damage. Clean or replace if necessary.

Spark Plug Gap: Check and adjust the gap according to the Powermate manual (typically 0.028–0.031 inches or 0.7–0.8 mm).

Spark Test: Reinsert the spark plug, ground the body to the engine, and attempt to create a spark. No spark may indicate a faulty ignition coil, wiring issues, a kill switch, or broken wires.

Kill Wire / Flameout Wire: Confirm the kill or flameout wires are correctly connected, as these must be in place for the engine to run.

Verify Air Supply

Air Filter Condition: Check the air filter for dirt or clogging. A dirty filter chokes the engine and prevents it from starting or running smoothly. Clean or replace as needed.

Intake Inspection: Look for any obstructions or blockages in the air intake manifold.

Fuel / Carburetor Issues

Edger Carburetor Cleaning: If fuel is present but the engine won’t start, the carburetor might be clogged. Clean the float bowl and jets thoroughly with carburetor cleaner.

Fuel Lines & Filters: Inspect for leaks, cracks, or blockages in fuel lines and filters.

Primer Bulb: If present, check for cracks or deterioration that might prevent fuel pumping.

Float or Needle Valve: A stuck float or needle valve can block fuel flow, causing start-up failure.

Confirm Compression (Engine Health)

Compression Test: If all else fails, perform a compression test. Typical small engine compression ranges between 80–120 psi.

Low Compression: Indicates possible internal engine damage such as worn piston rings, cylinder bore issues, or valve problems.

Cold Start / Hot Start Behavior

Choke Operation: If the engine starts when warm but not cold, verify the choke mechanism works properly.

Running Briefly Then Dying: This may indicate a lean fuel mixture or vapor lock issues causing the engine to stall shortly after starting.

By addressing these common edger engine problems and troubleshooting steps, you can solve most lawn edger not starting issues efficiently.

Troubleshooting Power Loss and Performance Issues in Powermate Edgers

Once the engine is running, you may encounter issues such as loss of power under load, engine bogging, stalling, or inconsistent performance. Here’s how to troubleshoot:

Overheating Due to Blocked Cooling Fins

Symptoms: Engine performance drops during long use, or it stalls in hot weather.

Causes: Dirt or grass buildup on cooling fins prevents heat from escaping.

Fix: Clean all cooling fins and exterior surfaces to allow proper airflow. Avoid long sessions without rest periods for the engine.

Blade Damage from Striking Hard Surfaces

Symptoms: The engine bogs down when cutting, and performance drops suddenly.

Causes: The blade is bent, chipped, or dull from impact.

Fix: Inspect the blade and replace it if damaged. Replace edger blade to restore proper cutting. Avoid using the edger near hard surfaces to prevent future strikes.

Worn Spindle Bearings or Shaft Play

Symptoms: Excessive vibration, blade wobble, and inconsistent cutting.

Causes: Bearings are worn out, or the shaft has too much movement in the housing.

Fix: Replace the worn bearings and check the spindle for straightness. Ensure all components are tightly secured.

Governor Spring or Linkage Malfunction

Symptoms: Engine speed drops sharply or doesn’t increase when working harder.

Causes: The governor spring is stretched, broken, or disconnected.

Fix: Reconnect or replace the spring and inspect the linkage for binding. Adjust tension to restore proper engine response.

Engine Running Too Rich or Too Lean at High RPM

Symptoms: Black smoke from exhaust (rich) or hesitation/bogging (lean) during edging.

Causes: Improper carburetor high-speed adjustment or air leaks in the intake system.

Fix: Adjust the high-speed jet screw as per the manual. Check intake gaskets and seals for air leaks and replace them if damaged.

Pro Tip: If the engine runs fine but cutting is poor, check the drive system, blade, and connections. The problem is often between the crankshaft and the blade, not the engine.

Check out this guide on Top 10 Common Lawn Mower Engine Problems and How to FixThem to keep your mower running smoothly all season long.

Fixing Blade and Drive System Malfunctions in Powermate Edgers

Properly addressing blade and drive system issues is essential for maintaining your Powermate edger’s performance and safety. Timely repairs help avoid costly damage and keep your equipment running smoothly.

Replace Damaged Blades: Bent, chipped, or dull blades strain the engine and reduce cutting quality. Remove the old blade and install a new one to restore performance.

Tighten or Replace Mounting Bolts: Loose or missing bolts cause blade wobble and unsafe operation. Regularly check and tighten bolts or replace damaged hardware.

Change Worn Drive Belts: A slipping or glazed belt causes edger drive belt issues that reduce blade power. Swap out worn belts and properly adjust tension to restore smooth power transfer.

Realign or Tighten Pulleys: Misaligned or loose pulleys cause vibration and uneven blade rotation. Adjust pulley position and secure bolts for consistent blade movement.

Repair or Replace Clutch Components: Worn clutch plates or faulty engagement mechanisms prevent proper blade spinning. Inspect and replace these parts as needed.

Replace Worn Bearings: Noisy or vibrating blades usually indicate worn spindle bearings. Swap them out and ensure the spindle shaft is properly aligned.

Clean and Lubricate: Remove debris around the blade and drive system, and lubricate moving parts regularly to prevent wear and malfunction.

Explore this guide on the Powermate tiller troubleshooting guide: common issues & fixes to easily identify and resolve problems for optimal performance.

Preventive Maintenance Tips for Powermate Edger Parts

A proactive preventative maintenance edger schedule is your best defense against downtime. Here are recommended practices:

Daily / Each Use

Check oil level and top up if necessary

Inspect the air filter and clean or replace

Visually inspect the drive belt, pulleys, and blade

Clear debris around the engine cooling fins, muffler, and intake

Tighten loose fasteners

Weekly or Every 10 Hours (or more often in dusty conditions)

Clean the air filter more thoroughly (or replace)

Lubricate pivot points, throttle linkages, bearings (if applicable)

Inspect spark plug condition, gap

Inspect guard screens, spark arrestors, and exhaust ports

Monthly or Every 25 Hours

Change engine oil (especially under heavy use or heat)

Clean carburetor, fuel system components

Check belt tension, alignment, and adjust

Inspect drive bearings and spindle bearings

Verify throttle linkage and governor are operating smoothly

Seasonal / End-of-Season

Drain fuel or stabilize it, run the engine dry

Store in a dry, ventilated area

Coat the internal engine cylinder with a small amount of oil before storage

Clean the entire machine, remove rust, and apply protective spray

Inspect and replace worn parts before next season

Use Quality Parts & Fuel

Always use recommended oil (e.g., SAE 10W-30 or manufacturer specification)

Use fresh, high-quality gasoline

Replace belts, filters, and bearings with OEM or equivalent quality parts

How to Stay Ahead of Common Powermate Edger Issues

Staying ahead means more than routine checks—it’s about spotting subtle changes and anticipating wear before breakdowns.

Analyze Usage Patterns: Track how often and intensively you use the edger to forecast when parts will need replacement.

Identify Recurring Issues: Keep a record of past malfunctions to spot patterns and address root causes rather than symptoms.

Plan Seasonal Overhauls: Schedule comprehensive checks before and after heavy-use seasons to catch wear early.

Invest in Training: Understand your Powermate edger’s specific mechanics to troubleshoot confidently and avoid guesswork.

Maintain a Spare Parts Inventory: Keep critical parts like belts and blades on hand to minimize downtime during repairs.

Consult Experts Early: Reach out to professionals at the first sign of unusual problems to prevent escalation.

FAQs

Why is my edger not working?

Your edger might not be working due to issues like a clogged carburetor, faulty spark plug, or fuel problems. Checking these components usually helps identify the cause quickly.

Why is my edger blade not spinning?

The blade may not spin because of a worn or slipping drive belt, a faulty clutch, or a damaged engagement mechanism. Inspecting these parts can help restore blade movement.

What kind of engine is on a Powermate edger?

Powermate edgers typically feature a 4-stroke gasoline engine, often around 79cc, designed for reliable and efficient performance. These engines provide the power needed for effective edging tasks.

Why does my Powermate edger pull hard but still won’t start, and how can I fix it?

Your Powermate edger may pull hard but won’t start because it’s not getting enough fuel or spark. Check the fuel, spark plug, and choke settings, and replace or clean parts as needed.

Validate your login